Safety Inspections Before Your Shift

It is imperative that the operator ensures the equipment runs in great condition and is safe to use within the facility.

There are many reasons why a forklift operator and material-handling professionals perform pre-shift safety inspections on their equipment. Many times the company mandates these inspections but it is an excellent practice to do them as a formality in every business.

Safety Inspections before Turning on the Engine

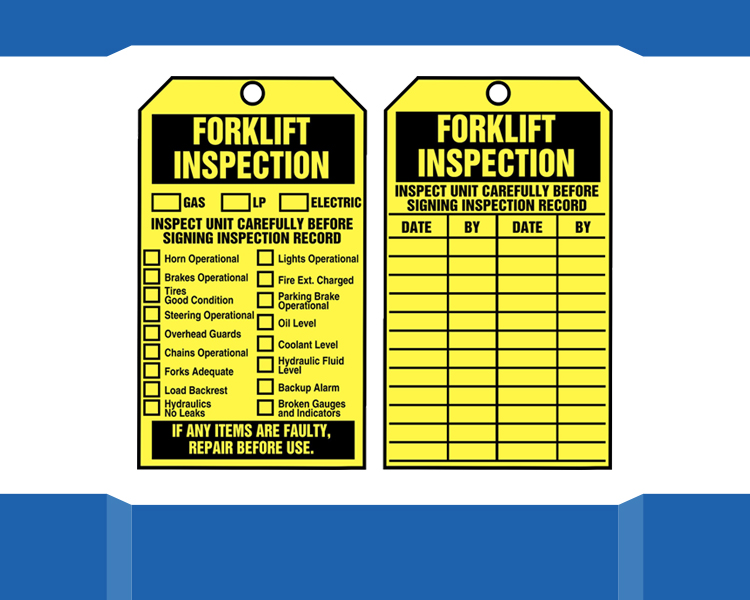

· Seat Belt: Check for any signs of damage to the seat belt, buckle, or retractor.

· Hoist System: Check for damage to the hoisting/lifting mechanism including the hydraulic hoses, cables, mast chains, and stops.

· Engine Belts: Check for signs of damage to the engine belts, including rips and cracks.

· Engine Air Cleaner: Check the condition of the air cleaner, and replace if it is dirty.

· Safety Appliances: Check if all the appropriate safety appliances are available. These include fire extinguisher, lights, horn, backup alarm, wipers and mirrors.

· Fluid levels: Check the levels of fuel, engine oil, transmission fluid, brake fluid, radiator coolant, and hydraulic oil. At the same time, check for leaks.

· Tires: Check the condition of tires and the tire pressure. Look for excessive wear, bulges, and cuts.

· Battery: Check the level of electrolyte, battery water and charge.

· Forks: Check the condition of the forks, in particular, the heel and top clip retaining pin.

· Safety Warnings: Check if the safety warnings are properly attached, legible and clearly visible.

· Overhead Guard: Check if the overhead guard is properly attached, or if it is damaged in any way.

· Hood Latch: Check if the hood latch is properly adjusted and fastened securely.

Forklift Inspections

When planning a long road trip, most people will take extra precautions to check their car or truck for any safety issues such as wear on tires, fluid levels and so forth. This is done out of concern for their safety. These precautions also help prevent the trip being cut short because of a breakdown. Breakdowns can lead to major repair costs, which can be even more expensive when you are not in home territory.

The same precautions should apply to forklift operators and material handlers on there own jobs. Even though these people may not be the owners of the lift, they have the responsibility of using the equipment everyday. It is imperative that the operator ensures the equipment runs in great condition and is safe to use within the facility.

Precautions should apply to forklift operators and material handlers on there own jobs.

Safety Inspections with the engine running

· Horn and Lights

· Monitors

· Forward/Reverse Drive Control

· Attachment Control Operation

· Forward- and Back-tilt Control

· Lowering and Hoist Control

· Cab – Defroster, Heater, Wipers

· Accelerator/Direction Control Pedal

· Steering Operation

· Gauges: Fuel Level, Engine Oil Pressure, Temperature, Ammeter, Hour Meter, Instrument

· Brakes: Service and Parking Brake

Confirming that your equipment is in stable and working condition before using it should never be seen as a waste of time. Forklift operators should eagerly perform these inspections not only because they are required, but also because they should care about their own safety and the safety of their colleagues. Companies should obviously want to avoid injuries within their company and should never have an employee operate faulty equipment. Responsibility and safety lies with the individual operators!